Portfolio

I am a highly-curious person -- I like to get my hands dirty with engineering concepts instead of just reading about them. From building physics demonstrations at home to working on design problems or unique contraptions, I always have a couple of on-going personal projects. Below is a sampling that exemplifies the range of topics and complexity of my tinkering.

CURRENT PROJECT:

Landyacht: a wind-powered sled on wheels

Some time in the mid 2010s I saw a video of something called a ‘landyacht’ and became obsessed. It looked like a three-wheeled bobsled with a sail sticking out of it, and the person sailing it on a beach was having a very good time. There’s a commercial version called a Blokart, but a lot of people build their own. Naturally I was interested in building my own but at the time I lacked the resources and skills to attempt it. Fast-forward to this year and I felt like I had the gumption to take a stab at it. I found some plans on an Australian forum which dozens of people had followed to great success, so I figured I could start there. The only problem was that the plans called for metal stock in millimeters and here in the U.S. we only have metal in inches. I had to convert the plans and make some modifications with an eye for structural strength. I also had to keep in mind that some of the parts had to fit into each other snuggly, so sizing one part affected other parts. It took me a dozen work days to build and it cost me roughly $700 in materials (the largest chunks being the windsurfing mast and the metal stock). But I’m incredibly excited to sail with it once a good day comes along. Here are some photos of the process:

Pedal-powered Catamaran a.k.a. PedalCat

While working on the Solar Splash project in college, our faculty advisor casually said something to the effect of, “it would be so easy to build a single-person catamaran that was powered by a bicycle crank.” And it stuck in my mind. Instead of one hull, a catamaran has two, which allows the boat to be wider without more resistance and thus less susceptible to capsizing. But having two hulls also allows them to be very narrow, to the point where it can be very drag-efficient. It turns out there have been many other people obsessed with the idea of person-powered catamarans spanning the last half-century. With the advent of epoxy-resin fiberglass and wood hulls, it became accessible for garage makers to build this kind of boat. Check out some of the images below of other people’s builds of multi-hulled personal boats… One of them holds the record for human-powered boats.

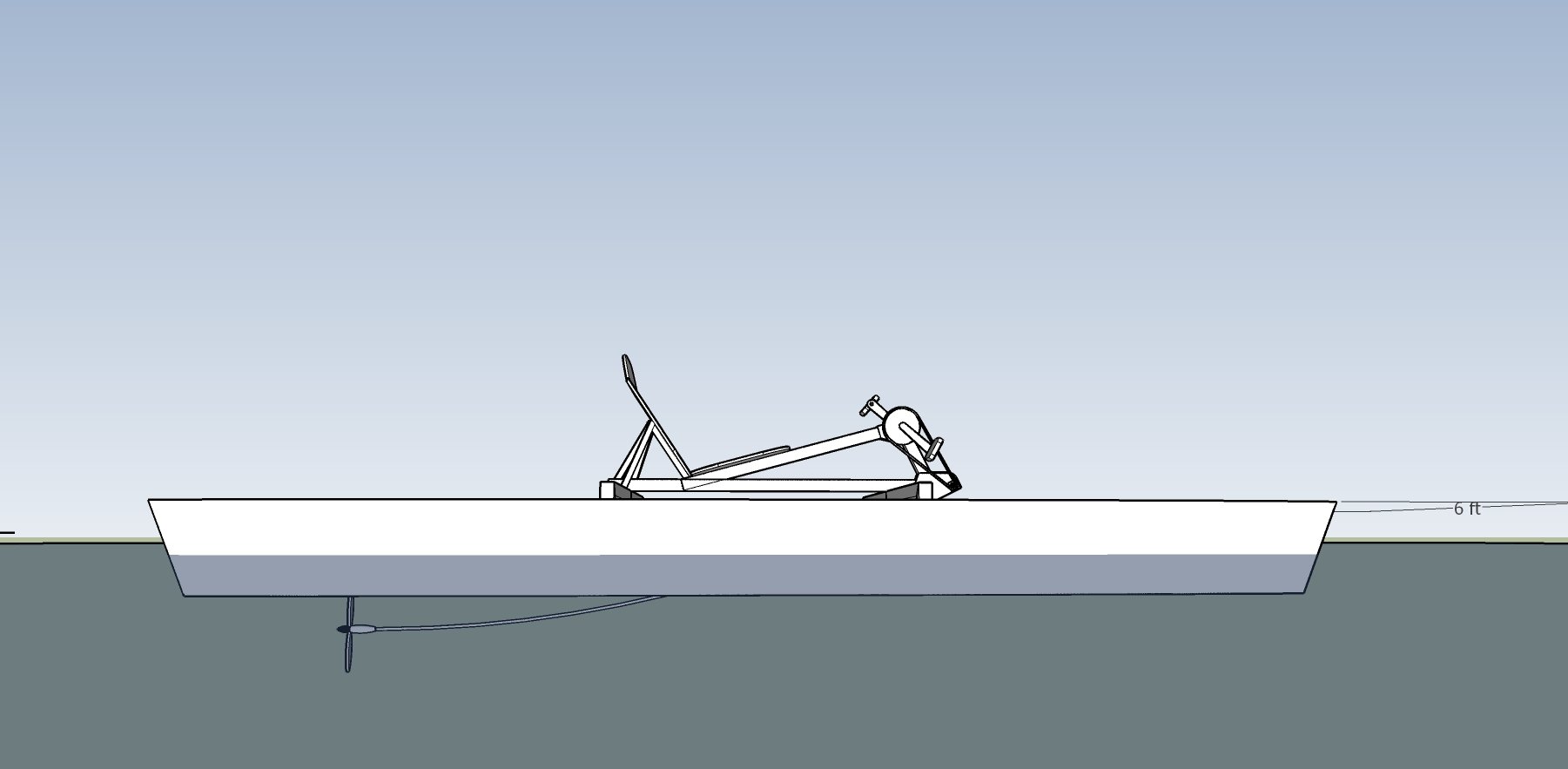

There are a few key engineering variables that inform the design of this kind of boat. Some of them are within my control, some are not. Firstly, the amount of weight the boat is designed to support is the biggest design factor. I will probably want to iterate and improve on this boat if it turns out to be sucessful, and that means reusing either the passenger platform that spans the two hulls, the hulls themselves, or both. I will air on the side of excess and design these hulls for the weight of two passengers, plus the weight of the system itself. A rough estimate for the total displacement required of the hulls is 500 lbs (myself, a passenger, and ~150 lbs total boat weight).

Second, the length of the system impacts almost every other engineering variable. The speed this boat can achieve under human power is almost entirely dictated by the length of the hulls. The boat speed (displacement regime) of a fifteen foot boat is 6 mph (2.66 m/s), a nice round number. The practical requirements for the boat are that I can lift and transport them in my car, and most car-topped canoes are 14 to 17 feet long so 15-foot hulls sound about right.

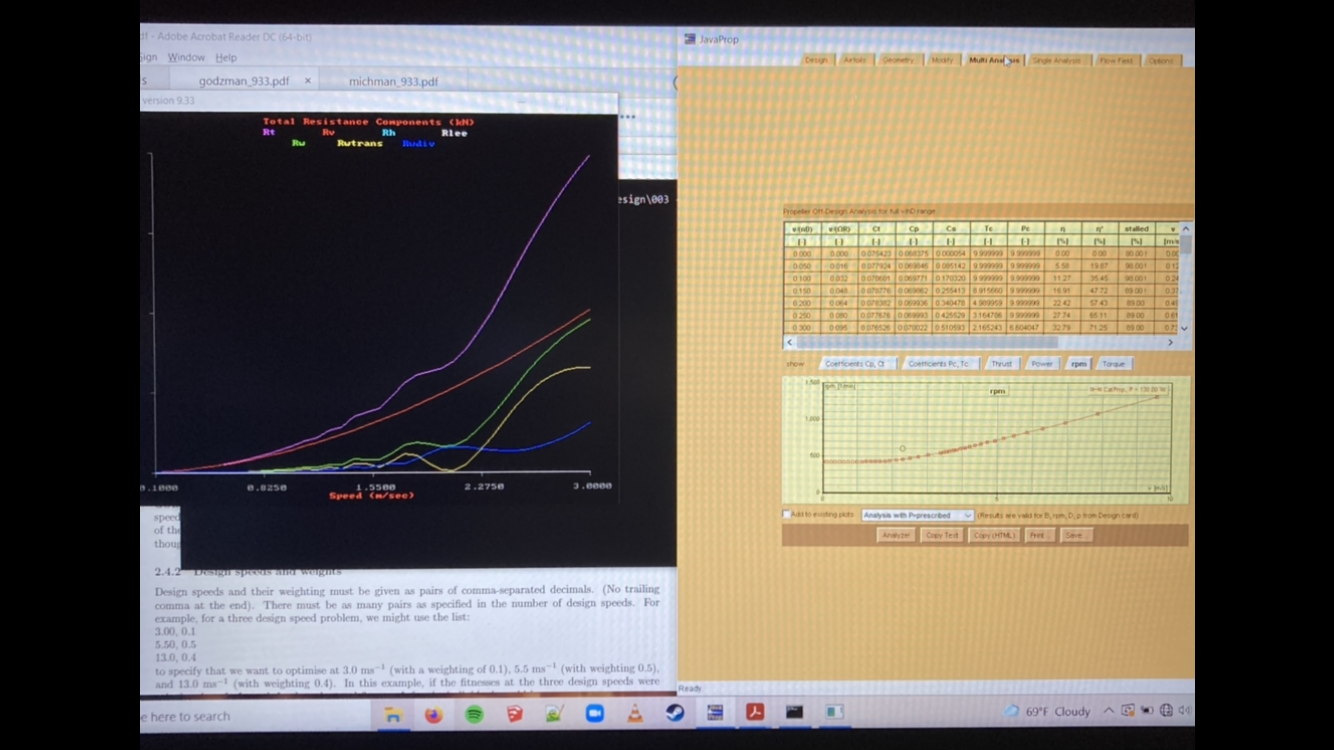

Third, the power supplied must match or exceed the power required to push the boat at its maximum speed. The power supplied by the pedaler is tricky, but estimates for a cyclist at long-haul endurance rates range from 100 watts to 300 watts. So I’ll settle on 130 W of power, to be conservative. I also must factor for the losses through the system before the power reaches the water, such as frictional losses in the pedal drive system, and slip between the propeller and the water. Propeller efficiency and power transfer are estimated pretty well at 80-90% with the type of two-bladded propeller I've selected. However I wanted to match the propeller to the drive system as close as I could so I used a program called JavaProp to model the different commercially available propellers and examine their performance characteristics.

A well-designed boat must match the performance characteristics of its propeller with its hull design. Mitchlet code (left) and JavaProp (right) were useful for estimating boat drag and propeller efficiency with some precision.

This chart compares the performance of the selected propeller and the a smaller 10ft-long hull design. The point where hull drag equals propeller thrust is the maximum achievable speed (2.3 m/s at 40N of drag). For the selected propeller, this thrust happens at 385 rpm. For a target leg turnover of 90 rpm, a gearing ratio of 4.25:1 is required. This is approximately the design point of the system, and that gear ratio can be achieved using a relatively simple gearing setup.

As for the power required to push the boat through the water: from first principles, P = FxV, or the power required to move the boat is equal to the total drag of the vessle at a certain speed, times that speed. We know the speed (6 mph = 2.66 m/s), but the force required to push the boat through the water, or the boat drag, is another difficult variable. Luckily this is a huge area of research and there are some tools I can use to estimate this with some confidence.

Estimating boat drag can be as complicated or as simple as you make it, depending on the amount of confidence and precision required in the answer. I wanted to be pretty sure of boat drag since there were bigger unknowns throughout the system. I knew of a research code called Mitchlet that computes Mitchells integral to estimate slender craft drag for low speeds. After fiddling with it, it was pretty easy to get an idea of the effects of different geometric variables on the total drag. I learned that drag did not change considerably between different hull shapes with the same beam and length, so I could opt for the simplest shape that I could make and still achieve a low-drag hull.

I determined that a 15ft boat with 10-inch wide hulls that are spread 5 feet apart and displacing about 500 lbs will produce 13 lbf [60N] of drag at 6 mph [2.6 m/s]. That equates to 180W of required power from the propeller, and accounting for a 50% efficient system, requires an output of 360 Watts from the driver. That is a sprint effort for sure, so cruising speed will likely be slower than 6mph.

The selected propeller will need to spin at approximately 400 rpm, and my legs need to turn over at a target 90 rpm. This means the required gearing ratio must be about 4.5:1. That’s it for the design specifications of the drive system. The rest is structural and design for manufacturing.

Above are some renderings of the boat design. Since lofting the hulls, I’ve decided to use parabolic strut hulls instead because they would be much simpler to manufacture. I’ve begun assembling the materials and parts for this build (see photos below).

I put down this project when I started working on the Windstrument again this spring. As I pick it back up I hope I’ll have a boat on the water perhaps by August or September.

Windstrument

When I was seven there was this giant marble track sculpture in my dad's office building and I used to beg him to take me to work so I could watch it over and over. As an adult I am often captivated by someone's kinetic sculpture or interactive art piece on the internet. I often dream of making different sculptures and kinetic machines of my own and the Windstrument is definitely the culmination of some of those dreams.

The goal of the Windstrument (wind+instrument) is simple: make a machine that allows the wind to play music. There are well-known examples of the wind making music (e.g. wind chimes). There are lesser-known art pieces where nature is the driving force for music, such as the "Zadar Sea Organ" by Nikola Bašić, "The Singing, Ringing Tree" by Tonkin Liu, or the aeolian harp (a historical zither that is played by the wind).

I love flying kites. My family has a picture of me at age 5 flying a kite with my dad and we often flew kites on beach vacations. As an adult, I keep a kite in my car in case I have some free time on a windy day. Sometimes the kite string will vibrate in strong winds, and if you hold it up to your ear you can hear it singing. This was the start of the Windstrument project, and I wanted to incorporate a kite into the design. Maybe I could amplify the vibrating kite string with a resonator? Or perhaps the kite could pull on a bass guitar string, changing the pitch it makes? Yeah, but what would 'pluck' or 'bow' the string to make it sound? Well I had stumbled on a neat fact while researching hurdy gurdys a few months before.

A hurdy gurdy is a medieval stringed instrument that is 'bowed' by a rotating wheel pressed against the strings. The bowwheel used to be wooden, but nowadays some are made from acrylic. The advantage of this wheel over a bow is that it can produce continuous sound with ease. (The same continuous sound can be achieved with a bow but it requires much practice). Moreover, a rotating mechanism lends itself well to a machine. So I decided to explore the concept of a stringed instrument that is tensioned by a kite and 'bowed' by a rotating wheel.

But what powers the wheel? Well a wind turbine of course! There are many wind turbine types and designs... surely there is one that can turn my hurdy-gurdy wheel. I started experimenting, prototyping turbines, measuring how much pull a kite produces in strong winds, measuring how much pressure and speed a wheel needs to produce a pleasant sound on a string, different resonators to amplify the sound, different structures for housing these mechanisms. I found a turbine design — called the Lenz2 — that produced high torque at low wind and rotational speeds, so I chose this design for my windstrument. I also loved the sound of a long bass string amplified by a big bass drum resonator. I kept trying to find a structural anatomy that could accomodate these elements, but it was difficult. I also struggled to figure out how to connect the kite to the sculpture. I dropped the project for a few months while mulling over these problems.

Then in September I woke up from a dream with some inspiration. I spent an hour that morning doodling my idea and refining it until I had something workable. That idea was an inverted pyramid. This pyramid idea is what I would pursue for the next six months.

The key notion behind the pyramid (one that would ultimately prove too artistic and not practical) was the idea of instability. The pyramid balancing on its tip is a visceral, literal representation of a state that is too unstable to persist. I wanted the pyramid to feel like the Monolith from 2001: A Space Odyssey... out of place and otherworldly... alien.

Another reason the pyramid struck a chord with me (haha) was because of a large radio tower close to where I live. South of Nashville, along I-65, you will see a strange broadcast tower on the side of the interstate. It is strange because it balances on a point and is held stable by eight guy wires. Typically a tower will have a wide square or triangular base, but no, this structure comprised of trusses and triangles was like a rhombus: pointed on both ends. It is such a strange sight and I could not stop staring at it. The power it possesed over my gaze is the same power I wanted to imbue in my windstrument structure. So I decided to pursue a structure that balances on its tip.

Of course, just like the radio tower, guy wires were required. The reason I woke up so excited about this idea is because I wanted the guy wires to also be the musical bass strings, performing two functions at the same time. This way, if the structure moved at all, that movement would be reflected in the changing pitch of the strings. It would be a tricky balancing act of all of the forces involved. This balancing act was appropriate as it exactly conveyed the precariousness I was going for.

I ended up building a six foot tall triangular pyramid out of wood. Wood because that was what I have the most skill with, and it had to be strong enough to withstand the tension of three bass strings (about 150 pounds!). Atop the pyramid, sticking out of the upside-down base would be the wind turbine. This design is unique because instead of rotating like the hands of a clock, it rotates like a mug in the microwave. It's called a vertical axis turbine for this reason. The axis of the turbine extends down through the pyramid and has a small acrylic disk at the end of it. The entire turbine-axle-disk assembly is balanced by pressing against three bass strings. The axle runs through one ball bearing at the top of the pyramid, and another at the tip near where the bass strings pass through the 'bridge' of the instrument. The strings are attached at one end at the three edges that makes up the triangular top. The other end was supposed to run through the 'bridge' in the bottom of the pyramid and outwards to a stationary base and act as guy wires for the whole sculpture.

After endless problem solving, I identified two fatal flaws in this design. First, the pyramid and turbine were just way too heavy for the strings to counterbalance. Second, the turbine itself was beautiful but not functional. It did not turn under the power of the wind and I suspect that was because of its weight and consequently the friction throughout. The result of these flaws was a scultpture that predictably was too unstable, and which did not do the one thing it needed to do (spin in the wind). I had been meditating on this design's flaws when I thought of a much simpler design.

Instead of the acrylic disk being coupled with the spinning turbine while the strings stay still, why not couple the strings to the turbine while the disk stays still? I drew up a design that resembled one from half a year ago... where the strings are vertical and make up a bird cage-like structure. This bird cage is balanced on the tip of a pole and is allowed to rotate. It rotates because turbine blades are attached along the circumference between the upper and lower disks. The strings are angled inwards, but opposite to the way they were in the pyramid design. This is because they press down on the acrylic disk instead of up on it.

This design was so much simpler than the pyramid -- I constructed the first prototype in less than six hours as opposed to six months. I first tested this design using strong fans to supplant natural wind. Then during one windy Saturday I took it out to the abandoned airfield in 18mph winds and watched it spin all by itself. The sound needs a lot of work (using a taller structure would allow for longer flat-wound double-bass strings which are the sound I was aiming for; and using a smaller disk would lower the buzzing noise by reducing the effective rate of rotation). If I made another prototype I would try to make it out of steel or aluminum because strength-to-weight ratio is critical to making this light enough to be spun by the wind. And instead of using true ball bearings, I would just use a point-and-cone bearing which has low enough friction for this application. I would make it 4ft long instead of 3ft to accommodate full-length bass strings, and I would experiment with a metal hurdy-gurdy disc instead of acrylic to see if it produces the same effect. Right now I am proud of how far I have gotten on this idea and I’m proud of my continued iteration on this idea.

Disco Head Chandelier

I came into possession of four foam mannequin heads and many pounds of small mirror tiles for making disco balls so naturally I had to make some disco-heads! Unfortunately for me the mirror tiles were not stick-on so I had to hot glue them one-by-one onto the heads (in retrospect I should have shelled out for some stick-on tiles). I wanted the facial features of the heads to be somewhat perceivable after applying tiles so I broke them into triangle halves to better fit the form of the faces. These two decisions turned a four-hour project into a thirty-hour project. But I was glad I did it because they turned out excellent.

I went to the thrift store and found a four-bulb chandelier fixture, took off the sockets and fixed the heads to it. I originally intended to run sockets back out of the mouths of the heads, and add a pair of cupped hands under each one. But I ran out of time and patience. So I left it as four heads that would spin like a disco ball. It's inaugural debut was at a friend's wedding in the karaoke booth!

Cooling Car Seat Cover

In the summer of 2022 my car's air conditioning was broken and it was going to cost a thousand dollars to fix it. The car was on it's last leg and I knew I'd have to get a new one soon. Before shelling out that money on fixing the A/C in a dying car, I thought I'd try a DIY solution to keep me cool in the car. I yearned for a solution that was as easy as flipping a heated seat switch, and I had an idea that might be that simple.

There are lots of DIY aircons that use ice and a fan to blow cool air at you, but a back-of-envelope calculation shows that it would take too much ice and too much fan power to be practical. I needed to transfer that ice-energy to my body more directly and efficiently. What about a liquid heat exchanger that ran from an ice bath to some coppor coils behind my back? I decided to pursue this 'liquid-cooled car seat cover' idea in ernest.

I had experience with closed-loop liquid-in-a-tube systems from my streamlines sculpture, so I decided to draw on that design to start. The system would be simple: a coil of 1/4" copper tubing would be submerged in an ice bath, and water flows through the coil. After losing heat to the ice bath, the water then is pumped through some vinyl tubing to a second length of copper tubing, this time snaking back and forth against the car seat, where the cool water will sap heat from my back. Then the water returns to the coil in the ice bath to repeat the process. The water is a working fluid transferring heat from my body to the ice bath. The big unknown was how much heat would be transferred from my body, and thus how long the ice bath would stay cold. My goal was to be able to refill the ice bath with some reusable ice packs once a day and stay cool all day long.

The other design need was a low-power pump to push the working fluid through the closed loop of tubes. I knew a small 12v peristaltic pump would do the job. This kind of pump is usually used in metering precise doses of medicine, or balancing liquid chemicals in small fish tanks. It's great because it doesn't need to be submerged in a reservoir to work. Instead it just squishes fluid through a rubber hose over and over to move it forward, keeping the closed loop closed. This pump draws very little current and could be powered by the 12v cigarette lighter outlet in my car.

The idea of sitting against a hard coil of copper tube is not ideal, so I decided to embed the copper in a foam cushion. I also marked on the cusion where my spine and scapula protruded and avoided putting tubing there. In the end I used about five feet of tubing and sewed it tight to the foam cushion. It was not uncomfortable at all. I added a pulse width modulator circuit to the pump to let me throttle the speed of the fluid flow in case that was important. I made a little foam cooler to put the gallon ziplock with iceblocks and water in. I connected the copper coils with vinyl tubing by gluing and zip tying them closed. The cooling car seat cover was complete!

In July it typically reached 140 degrees F in my car, even with the windows cracked. And in the dead of summer in Nashville, it usually stayed around 90 degrees in there regardless of air flow. But the copper cooling coils would cool down to around 55 degrees and were a great relief while driving (they stayed super cold even after using the device for a long time!). Even better, this system stayed cool throughout the day with only a couple of reusable ice packs in the cold reservoir. And it used a lot less power than a conventional air conditioner so I was even saving a little fuel (small condolences for having a broken A/C). Overall the project was a huge success and the car seat cooler saved me from overheating during a hot hot summer of driving. I was a sweaty mess getting to and from anywhere, but the point is this is a critical cooling technology when you're in a pinch with no car A/C. I wonder what other settings would benefit from this simple method of keeping cool.

Wood-fired Hot Tub: Applying engineering concepts

In October 2023 I saw an instagram post about someone who built their own wood-fired cedar hot tub. It looked so nice to have a hot soak outdoors in the cold. I was so jealous and thought, "I could do that!" in an uncommitted sort of way. But after puttering over it in my head, I really did think that perhaps it was something I could do, and have done before winter so I could enjoy it.

The first thing I always do is a research spree just to get my gears spinning. But also to mull over important questions not just like "How?" but stepping back and asking "Why?". Sometimes the 'why' is less obvious or more nuanced than it first appears. I came up with two good reasons: a) it would be a good project to learn new making skills. As a bonus at the end, if I had a working wood-fired hot tub, then b) it would be nice to enjoy a hot tub during the cold months.

On a cursory review of other people's projects and commercial products available, I found there were several designs that may or may not have achieved the same result. In one camp was a round cedar wood tub, with a built-in stove that used some clever science to heat the water while submerged in it. This approach emphasizes the construction of the cedar tub, and presented a pre-designed solution to the wood-fired heating part. After researching the design of the submerged 'snorkel' stove, I decided that I would be unsuccessful at building one myself. Snorkel stoves are commercially available, but cost upwards of $1,000. That was too much for me and did not check enough of the DIY requirements to be fun.

This commercially available 150-gallon stock tank from Rubbermaid proved to be the easiest solution for the tub itself.

Another design was a stock tank with a big stainless steel coil of tubing that stuck out of it that you light a fire under and it passively circulates warm water throughout the tub. The drawback of this design was that it likely did not heat the tub quickly at all, and several reviews said as much. Indeed most of the heat of the wood fire is lost to the atmosphere, and from first principles that's too much heat loss to heat the water in a meaningful timespan.

A key drawback of the DIY hot tub designs I saw out there were how little insulation they had. Intuition, and a simple heat loss calculation, show that an uninsulated tub of hot water placed outdoors in the winter air will very quickly cool down to an unenjoyable temperature. And even if the tub experienced zero heat loss to the environment, it would take hours to heat it up from the temperature of the tap (about 55 degrees F) to a comfortable temperature of 90 or 100 degrees. So insulation is a very important part of the heating equation, and cannot be avoided.

I always ask myself if I really want the end result and not the project itself. In this case: "Do you actually just want a hot tub?". The answer was no. I actually had a hot tub at the house I was rooming at in Boulder a decade ago, and even in the frigid and snowy Boulder winter, the hot tub was fantastic, but not so fantastic that I would want one for myself. I wasn't willing to dish out the money for an outdoor hot tub solely for the sake of enjoying the tub. But the idea of a fun DIY project whose end result may be a working hot tub -- that was enticing enough to me to pursue it. I love thermofluid design, fire and woodworking and this project brings all of them together.

What would be the dealbreakers? If building or operating the hot tub was unsafe, or if the time or money required was too much, then those would be deal breakers. And in the end I spent quite a lot of time and money on this project. But I set a budget at the beginning and roughly stayed within its bounds, so I am happy about that trade-off.

After deciding to pursue this project, I had to write down my project requirements. Firstly, I had to investigate whether heating the tub by burning wood was effective, safe and economical. After all, that was the allure of the idea -- that it could be an economical way to achieve the same result as an electric water heater. Secondly I needed to assess the skills and materials required for the project, and determine whether the project was even in my wheelhouse. The materials that withstand heat and the outdoors were limited to metals, masonry and treated lumber. I was fairly sure I could tackle the woodworking portion, but I didn't have much experience with metal fabrication, and zero experience with masonry. Thirdly, after doing some back-of-envelope calculations (and from intuition) I knew that squeezing enough energy out of firewood was going to be difficult, and would need a lot of engineering for efficiency.

I had also maintained pools before and knew what a hassle keeping chlorine and hardness levels in water was. It is a full-time job. So I was attracted by the idea of having a very small tub volume that could be emptied after every couple of uses, to avoid using chemicals at all. I knew how disgusting hot tubs could get if you didn't clean and maintain the water correctly. So a key requirement would be ease of maintenance of the water.

Where to put the hot tub was another issue. We have a big back yard that is fenced-in that the dogs can roam around in freely. A big tub of water is a potential hazard if it is too close to the foundation of the house. A wood fire, in whatever container it's in, is always a potential hazard around houses, dogs and people. There was the potential hazard of becoming a mosquito breeding ground in the warmer months if the water was not treated and contained properly. There's also the issue of ground saturation. That backyard is not graded right and has trouble draining after it rains. If I create a high-traffic work area in saturated ground it will become a muddy mess (it did end up becoming a mud pit, more on that later).

Also the cost of the water itself may be an issue. A quick search on how much a bathtub holds returns about 50-75 gallons. So filling up this hot tub would be equivalent to filling up the bath twice. So it would be reasonable to refill the hot tub nearly as much as you would take a bath. However, as I'll discuss later, it wasn’t the water itself but the heating process that was the real bottleneck in practice.

So, all-in-all, here are my customer requirements (the customer being myself):

The project shall not pose a significant hazard to life or property.

The project must stay under a stated budget. The precise budget is TBD but likely within the $1,000-2,000 range.

A successful project will be a tub of water that can be heated up to a comfortable temperature (about 95 degrees F) using only firewood as the energy source, and stay comfortable for the duration of a bath (about 45 minutes).

The project should be achievable given infrequent bouts of effort on the weekends and the occasional weeknight.

The project design should be achievable using my existing skills and knowledge and a maximum of one or two additional skill sets.

A working hot tub should be achievable in time to enjoy it during the cold months (meaning before the end of February, ideally sooner).

Focusing on the engineering requirements:

The hot tub water temperature needs to be 95 degrees F at the end of the heating process.

Heating the water from tap temperature (55 F) to soaking temperature (95 F) must not take longer than 12 hours (the longest I can tend to a fire without getting discouraged).

The heat source shall be the combustion of kiln-dried firewood. (I have no experience with propane, and electricity is expensive).

The tub shall be large enough for one person to fit comfortably, two people by getting cozy.

After reading about several others' attempts at building a leak-proof cedar tub and failing, I decided to reduce the chances of disappointment by purchasing a pre-built tub. The heating part of this project was plenty hard enough that I wanted to take this mode of failure off the list. There are several kinds of tanks and tubs that I could get, but I ended up getting a stock tank for watering farm animals made by Rubbermaid. It has a capacity of 150 gallons, is made of molded polyethylene which holds up to high heat and resists weathering and cracking, and has a built-in drain plug at the bottom of the side wall. The construction of it meant it could withstand a human or two leaning against the walls along with the forces of the water. It has a smooth lip at the top, meaning it wouldn't be uncomfortable to rest your arms over the sides. And the bottom was structurally reinforced so that stepping into it wouldn't punch a hole in the bottom. Additionally, it was able to fit into the back of my car, so transporting it wasn't going to be an issue. So I had a tub!

The question then became how to insulate the tub. That was easy -- fiberglass batting, if kept dry, was a great choice. In addition to batting I could get a stiff insulation foam board to surround the batting, keep it dry, and give structure to the outside of the tub. I knew where to get discarded outdoor banners which would serve as the final weatherproofing of the tub. After calculating the heat loss of the hot tub through this amalgam of insulation, I was satisfied that it would hold heat long enough to heat up and enjoy the tub.

The next issue was how to heat the tub water safely and efficiently. Scouring the internet for estimates of how much energy is contained in firewood I landed on about 8000-9000 Btu/lb of kiln-dried wood. For context, you can buy 16-inch split logs by the cord for anywhere between $200 and $400. A cord of wood is nominally a stack of logs measuring 4ft x 4ft x 8ft, but the exact amount of wood in a cord will vary from distributor to distributor. But very roughly, there are about 600-800 split sticks of wood in a cord, which weighs anywhere from 2000-5000 lbs. So one log of kiln-dried hardwood costs about 50 cents, weighs about 5 lbs and contains about 35,000 Btu of energy before losses. These numbers are very rough, but good for order-of-magnitude calculations. Next let's determine the energy required to heat the water from 55 to 95 degrees Fahrenheit. Let's not forget that the person in the tub will displace water, so we don't want to waste energy heating water that will be spilled when a person gets in the tub. A 200-lb person displaces approximately 25 gallons of water, and we don't want to fill the tub up to the very top so let's say we only need to heat 100 gallons of water. To heat up 100 gallons of water by 40 degrees F would require 33,000 BTU given a 100% efficient system. That's only one log of wood! But let's say the system (from burning the wood, to transferring the heat to the water, to the heat losses to the atmosphere) is only 10% efficient. That means I would need to burn ten logs (50 lbs) of wood to heat up the tub. That’s a practical amount of fuel! Even 100 lbs of wood to heat the tub (5% efficient system) is an acceptable cost. Now the task is to design a heating system and insulation with an efficiency of about 5-10%. And that's the biggest unknown of this whole endeavor.

Did you know: fire isn't the result of wood burning. Fire is the light and heat emitted from gasses combusting. What gasses, you may ask? The volatile organic compounds that are emitted when a solid material undergoes pyrolysis and breaks down at the molecular level. I struggled to understand what 'fire' is until I grasped this concept. The wood isn't burning, but the gasses it emits are. The saying goes that the recipe for fire is oxygen, fuel and heat. What's the heat part? Once a fire is lit, doesn’t the reaction continue until there is no more fuel or oxygen? Actually this isn’t the case. If a fire does not produce enough heat during combustion to maintain ignition temperature, it will go out. In the case of solids like firewood, it also requires enough heat for the wood to undergo pyrolysis. That's why heat is necessary: maintaining ignition temperatures and pyrolizing the wood into combustible gasses. How does this apply to the wood-fired hot tube?

In researching efficient stove designs, the key fact that kept popping up was reaching high temperatures and getting enough oxygen. Why is it important to get the fuel wood really really hot? In order to efficiently break the fuel down via pyrolysis, it's got to be really really hot. So efficient stoves tend to be designs that are insulated enough to build up heat to really high temperatures and reach that point of efficient combustion.

One such design is the rocket stove, so named because of the 'wooshing' sound it makes at the air intake. Fires like the ones in a fire pit or charcoal grill don't burn very efficiently because they lack the necessary oxygen and the necessary heat for a complete combustion reaction with the supplied fuel. But rocket stoves ensure lots of heat is built up and lots of oxygen enters the system to burn nearly completely. It does this by choice of materials and geometric design. The choice of materials for a rocket stove are either double-walled steel or ceramic firebricks. Especially for the firebrick, heat is not transferred easily through the brick, so it traps heat on the inside of the combustion chamber. This heat builds up as the rocket stove continues to burn, and reaches equilibrium with heat loss at some pretty high temperatures (1000-3000 degrees F!).

The second missing piece is oxygen. An open campfire stiffles itself of oxygen because the byproducts of combustion, CO2 and water vapor, are not efficiently removed from the area of the flames, and so new oxygen-rich air cannot make it to the reaction quickly enough. This is why chimneys were invented. They funnel the combustion byproducts up the chimney, aided by the buoyancy of the hot air, away from the fire and draw fresh oxygen-rich air into the logs. A rocket stove is just a very well-insulated combustion chamber and chimney. From the point of view of the combustion reaction, the length of the chimney equates to the time available to combust before it mixes with the ambient air and cools down. So the longer the chimney, the more time the reaction has to take place and the more volatile gasses can be burned. A rocket stove has a tall chimney, at least four times longer than the combustion chamber where fuel and oxygen mix. Coupled with the very high temperature inside the whole stove, this allows a very efficient combustion to take place.

Because the principles behind the rocket stove are so basic, my intuition told me that any efficient wood stove in Earth's gravity and atmosphere would look very much like the existing rocket stove designs. So I bought a book on rocket stoves, as they applied to residential heating applications. It's called Rocket Mass Heaters by Ianto Evans. Several people have written books on rocket furnaces that heat homes (called rocket mass heaters), but Ianto Evans' book had step-by-step instructions on a design that was appropriately sized for my project. The rocket stove would take wood fuel, split to the size of kindling, and burn it nearly completely, such that the exhaust of the chimney would be hot air that is several hundreds of degrees Fahrenheit, and water vapor. I've got my efficient wood burning furnace, now I need to transfer that heat to the hot tub water!

Luckily I had studied thermofluids and heat exchangers in engineering school so I knew where to start. At first I thought I could stick a coil of copper tube in the heat riser chimney of the furnace and run the tub water through that. But the rocket stove was undersized and I knew the heat exchanger wouldn't be very efficient. So I started thinking about a dedicated heat exchanger, one that was based on tried-and-true engineering designs and that would sap as much heat from the furnace exhaust as was practical.

From first principles a heat exchanger's efficiency will depend on a few variables. First is the starting temperature of the two fluids flowing through it. In this case, the air's temperature will be somewhere between 500 and 1000 degrees F leaving the rocket furnace (experimentally, it turned out to be around 500). The water temperature entering the heat exchanger would be between 55 and 95 degrees F. In some heat exchangers, the fluid temperatures are very near each other, and thus as the temperature difference between them decreases the efficiency drops off to nearly nothing. But in this case the temperature difference is constant, practically speaking.

The second factor in heat exchanger efficiency is the material that separates the two fluids from mixing, and how much surface area it has. In this case it was commercially available copper tubing, typically used for residential plumbing (specifically Type M copper tubing which has a thinner wall and thus less resistance to conduction). Joining copper tube and fittings was a simple matter of soldering the joints together, and the water flowing through the tubes would keep the solder from re-melting. (** this is a critical failure note: if water is not flowing through the copper tubes in the heat exchanger, they run the risk of uncoupling and leaking water. water must always be flowing when hot exhaust air is flowing through the heat exchanger).

The third factor in heat exchanger efficiency is flow rate of both fluids through the exchanger. This was largely out of my control, since I did not plan on installing a fan to circulate the 500-degree air through the exchanger, and I would have to rely on the convective pull of the chimney to circulate the hot air. Using airflow footage and the dimensions of the furnace, I guestimated that the hot air flowed through the exchanger at about 600 cubic inches per second. As for the water flow rate, I also was at the mercy of whatever commercial pumps I could get my hands on. I did a rough calculation of losses through the system and thought I would be happy to get one to two gallons of water through the heat exchanger per minute. Experimentally I achieved about 10 fluid oz per second, or 4.6 gallons per minute.

The fourth and perhaps most critical factor was geometric in nature -- the effective length that the air would have the travel within the heat exchanger, and the surface area of the pipes that would come in contact with that air. The more surface area, the more heat the water could sap away from the exhaust. Typical tube-and-shell heat exchangers have a bunch of tubes routed through a shell container such that one fluid flows through the tubes, and the other fluid flows around the tubes but still are contained inside the shell. To increase the effective length that the second fluid travels, baffles are installed in an alternating fashion to force the second fluid to snake up and down around the tubes. Well in my heat exchanger I would need some baffles as well, to force the air to spend more time flowing over the copper tubes. I also made an additional design choice which was to split the copper pipe into four pipes, so that four times as much heat exchange surface area was available. The flow rate would be the same since they join back into one pipe at the end. If I wanted to increase the heat exchange surface area even more, I could add copper or aluminum fins to each pipe which would conduct additional heat to the water inside the pipes. In the end I constructed a heat exchanger out of a propane smoker box, 3/4” copper tubing and galvanized sheet metal. The air ended up making 8 passes over the copper tubes.

An approximate measure of the heat exchanger's efficiency would be defined by the difference in temperatures going into it versus the difference in temperatures coming out of it. Because water has a heat capacity four times greater than air, I expected to see a very large difference in air temperature produce a relatively small temperature difference in the water. (After experiments, that proved true... Exhaust from the furnace started at about 500 degrees F, then after passing through the heat exchanger it would be as cool as 100 degrees F. In contrast, water entering the heat exchanger would be, say, 55 degrees, and exiting the heat exchanger would only rise by 3 degrees. Throughout the project I consistently got a temperature increase in the water of about 2-3 degrees F, regardless of whether it was cold tap water or nearly-hot 90-degree water. (I actually measured the temperature difference between the supply and return hoses, and it did decrease as the tub water got hotter, as expected. See figure below).

With all of the system elements figured out, I needed to put them all together. To recap: firewood is fed into a rocket stove, which produces hot exhaust air. The exhaust flows through a heat exchanger where water is being pumped through. The water heats up a small amount before returning to the tub. As the water makes more and more passes through the heat exchanger, it gets hotter and hotter. Eventually the hot tub will reach a comfortable temperature and hopefully stay warm for multiple uses. Here are some photos of the final build.

Of course I wanted to take lots of measurements throughout the system while I heated up the tub — see the above plot. The red data points are temperature measurements at the water return from the heat exchanger, so naturally it should be warmer than the supply water in the tub (blue data points). The lines are linear best-fit regressions. A note about this data: it was pieced together from two different firings of the furnace over the course of two days. You can see at about hour 8 the temperature dropped by five degrees. This is because I went to sleep and wasn’t feeding the fire so the tub water cooled off a little bit. When looking at this data I note a couple things. Firstly, the temperature change over time was pretty variable… some hours it would jump three degrees, other hours it only increased by one degree. I have a good hunch of why this happened. During the experiment I noticed that the fire did not burn at a constant intensity. It burned hottest right after I fed it more firewood, and in about 25 minutes was not as intense and I would need to feed it again. The intensity seemed to depend on how much firewood was in the feeder, as this determined both how much fuel there was to burn and how much air was getting to the combustion chamber (more fuel meant less air because the fuel feeder and air intake used the same opening). This was expected, as I wasn’t prepared to tend to the fire constantly for eight to twelve hours at a time. Indeed one of the allures of this type of furnace was to be able to ‘set it and forget it’ for a half-hour at a time.

The second observation I make from looking at the data is that, regardless of the local variations in temperature increase, the tub did heat up approximately linearly as a function of time. I worried that, as the tub water got hotter, the amount of heat getting passed to the tub would decrease. That did not seem to happen. Instead, given a constant feeding of the furnace, the tub will heat up at a constant rate, and I can predict roughly how long it will take to heat it from a starting temp to a target temp. For instance, from that experiment it takes approximately 14 hours to raise water by 50 degrees, for an average rate of 3.5 degrees F per hour. This is a great rule of thumb to have on hand.

Equally as important as efficiency in heating the water was how well the tub retained heat while it wasn’t being heated. This was simple to measure – I took the temperature of the surface of the tub water while the fire was out. Over several days in which the outside temperature fluctuated between 50 and 70 degrees, the tub cooled down from a maximum of 100 degrees F to 70 degrees F. The tub also cooled at a rate much slower than the rate of heating. Between 70 and 90 degrees F, the tub will cool at about 0.33 degrees F per hour. This is about ten or twelve times slower than the tub heats up. I was encouraged by these results because it meant that it wouldn’t take 12 hours every time I wanted to take a hot bath. If I had heated it in the last few days, chances were it would take significantly less time than the initial firing to get it back up to bath temperature. Here is a look at the approximate energy flow of the system:

This Sankey diagram shows energy flowing through the system, in units of BTUs per hour. After combustion of the fuel, most of the energy is transferred to the exhaust air (some energy heats the furnace). Then exhaust air transfers its energy to the heat exchanger pipes before escaping out the chimney. After water is heated by the exchanger, it travels to the tub where most of it goes towardds raising the temperature of the tub (some energy is lost through the hot tub walls and to evaporation. All-in-all the system has an overall efficiency of about 8%, which was in the range of target efficiency!

There were disappointments from this data as well. The ideal goal was to be able to come home from work at 5 and have the tub hot by 8. However, it took much longer to heat the tub up, suggesting I should re-use water from one firing to the next. The idea of re-using hot water meant running the risk of bacteria growth. Ideally, it would have taken a fourth of the time to heat up so that I didn’t have to re-use water and could just fill it with clean water every time I wanted to take a dip… the cost for new water was acceptably low that I would have preferred it that way. So increases in the heating output of the furnace, or increases in the heat exchanger efficiency, are necessary. I will write about possible improvements to the design later on.

I am writing about this design like it was exactly what I designed at the start, which is far from true. In reality the design of the hot tub system went through countless changes and iterations. It took over five months before I could enjoy my first hot soak. I spent $1,763 on tools and materials (as close as I can account for. And about $1100 of that ended up in the final build). I almost burned down the house one time, and I constantly worried about the dogs choking on random construction debris in the yard. Now three months since the last freeze and the last soak, I look at the project with mixed feelings. If I were to keep using the tub, I would have to make some changes to the design to cut down the amount of time it takes to heat it up.

Improvements I would make:

Add heat fins to the tubes in the exchanger

Build a deck for the tub for better appearance, structure and access

Clad the tub in cedar boards for better appearance

Place the heat exchanger directly above the heat riser of the furnace to decrease losses

Use a slightly stronger pool pump whose power can be adjusted

Separate air intake hole from fuel feed hole. This way fuel clogging the feed tube won't block air intake; air intake can be throttled; fire won't climb up the gravity feeder if it’s sealed shut with a cover.

Make the fuel feeder get bigger slightly towards the bottom, to discourage wood from jamming and getting stuck.

Perhaps use old car radiators as heat exchangers, one on top of the other inside the heat riser.

At the end of the day, it takes a long time to heat up this water. I'd want to keep it hot as long as possible and reuse it if I soak in it every day. That means I'd have to use chemicals to keep it clean and prevent bacteria from growing. If the above changes result in significantly shorter heating time from tap temperature, I could afford to drain the tub after each use and not worry about bacterial growth.

Moving forward, it will be very simple to use this tub as a cold soak tub during the hot summer months. This will afford me a break from working on this project, and if I decide to continue it, I won’t have to make that decision for a long while. I’m proud of what I’ve accomplished, and if I choose to keep working on it, I look forward to making it even better!

Workshop Workbench

I needed a workshop assembly table and outfeed table for my tablesaw, so I looked through some plans on etsy and bought one that would fit my needs. I liked the simplicity of this one and it was good for modifications later. The frame is a simple 4x4 construction and the top is made of a 3/4-inch-ply sandwich. I routed two grooves so tablesaw sleds can move through it and chamfered all the edges. I'll add a woodworkers vice, finish out the bottom with shelving and cabinets, and perhaps add a router underneath the other end for additional functionality. It has been the most important tool in my workshop to date.

Belew’s Bellows: Starting a woodworking business

It started when I picked up a pair of fireplace bellows at a friend’s house and didn’t immediately understand how it worked. Since I couldn’t tear it apart to find out, I googled it and was fascinated by the simplicity of its one-way valve. I went home and constructed a couple of my own bellows. The process was fun and there were just enough functional constraints that I kept coming up with ideas for non-conventional bellows or unique designs. It was fall 2020 so I had a lot of time at home to tinker. I showed people my work and they asked me to make them a personalized bellows, so I started making those. At some point I realized I wanted to dive deeper and have a go at my own bellows business (which of course I would name Belew’s Bellows!).

Three months after I picked up my friend’s pair of bellows, I was in full production mode. I had designed over a dozen unique bellows, many of which had custom artwork or were unconventional in form. I was accepted as a vendor at several craft fairs. I was getting orders from strangers all over the country at my online Etsy store. I was humbled and encouraged at such quick success. In addition to solving engineering and artistic problems, starting a business also allowed me to flex my skills in accounting, sales, vendor management and component sourcing, fail-fast philosophy, design for assembly, fostering customer relationships, social media and promotion, rapid iteration and pivoting strategy, and so much more.

To see more bellows, check out my Etsy store (belewsbellows.etsy.com) or my Instagram @BelewsBellows.

I plan to continue Belew’s Bellows as a side gig and I am excited to carry these skills forward in another engineering role.

Workshop Design and Buildout

For years the only workspace I had was my bedroom, where projects would take up space and create hazards. I was unable to work on some of my messier projects because I had to sleep there as well. But when I moved into a house in Nashville last year, I was beyond excited that there was a little-used half-garage in the back. I cleaned out all the junk that was being stored in there, designed and assembled worktables, and built out my dream workshop. It is this space that has enabled me to chase my more ambitious, messy projects (including a fireplace bellows business!). So far I’ve worked on electronics projects prototyping, fire tornado demo testing, furniture repair and refinishing, bellows fabrication, and sail making. This room is now my favorite space to be in. I cannot wait to document the fun things I’m creating these days!

Engineering Team: Solar Splash 2018

During my senior year I joined an extracurricular engineering team called Solar Splash, which designs, builds and races solar-electric boats. I first led as the mechanical project group leader, then as the team leader, to organize members, raise funds from sponsors, manage the project planning, design mechanical and electrical systems and catalyze learning opportunities for my teammates. Over nine months we went from optimistic rookies to winning the main sprint and endurance events, and finishing third place overall. I learned countless skills and lessons from this exciting experience and I'm glad that UNO students now have this opportunity to learn outside of the classroom.

Nudibranch Mardi Gras Costume: Ambition, Vision, Experimentation, Celebration

Many of my projects are the result of multiple interests colliding in my head. This project was born after moving to New Orleans and thinking about Mardi Gras costumes, scuba diving and a fascinating emerging technology called ‘soft robots’.

I love scuba diving. Every time I sink below the water’s surface to see the wonder down there, I am inspired. My favorite organism to spot is the nudibranch, or sea slug, but they are notoriously hard to find since they’re so small (about a centimeter long). I am especially enamored with the Flabellina Affinis, a purple sea slug with a cape of tentacles and an alien-looking head. While thinking about how to dress up for my second Mardi Gras season, this sea slug kept coming to mind.

I also had been learning about ‘soft robots’, or molded elastic pneumatic actuators whose asymmetric inflation is engineered to create useful motion and exert force in delicate environments. I really wanted to try my hand at creating a soft robot. It occurred to me that, more than a costume, my nudibranch creation could function as a puppet, with me actuating its two front tentacles to interact with other people. With this idea, I was determined to create a wearable soft-robot nudibranch costume for the 2017 Mardi Gras season.

This costume required a lot of research and experimentation. Since the soft robots I was emulating were made of an elastic rubber material, I decided to make the static parts of the costume out of silicone for its similarity. Silicone is a fickle material and modifying its properties with other additives proved doubly tricky. I spent weeks testing different silicone mixtures and finally achieved a useful building material. Over three months, I learned a lot about documenting my methodology to get repeatable results. I practiced skills like adhering to a schedule when my only accountability was to myself. I learned to scale my goals and set achievable milestones when the initial scope was overly-ambitious. I am proud of what I learned and achieved and would love to use some of these testing and fabrication skills again.

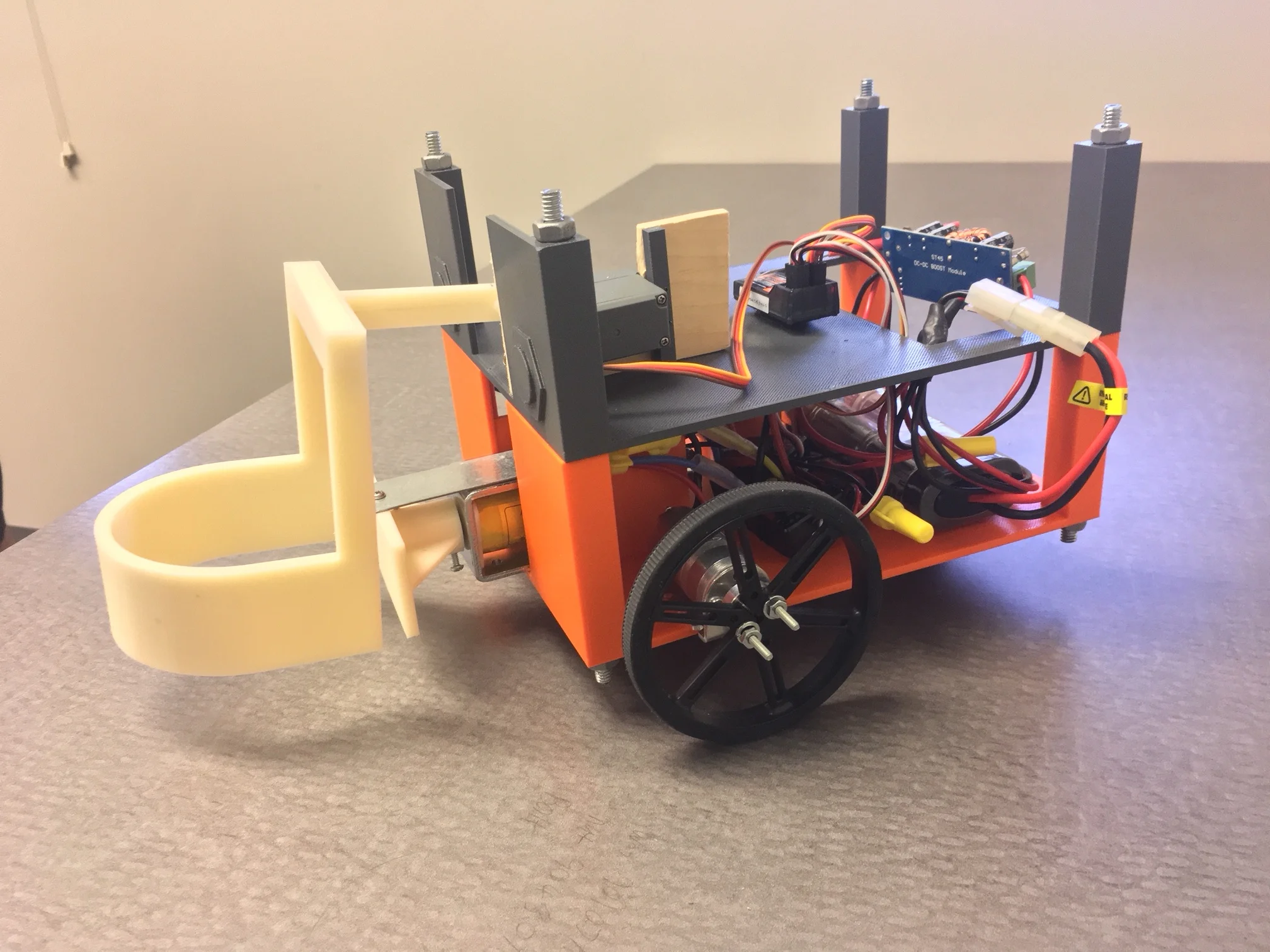

Senior Project: Mini Soccer Robot

For my senior engineering design class, we were tasked with building a device to play soccer in accordance with ASME competition guidelines. To build a winning design, my team used business and engineering tools such as a SWAT analysis, Quality Function Deployment, functional decomposition diagrams, benchmarking, Computer Aided Design, Finite Element Analysis, and project planning tools such as Gantt charts. It featured responsive steering, long battery life, electromechanical dribbling and kicking capabilities and durable construction. Though it was a prototype, it achieved all of our engineering goals and won the 'Best Overall Design' award.

Streamlines: A Fluid Sculpture

This is a fluid sculpture that depicts a snapshot of high-altitude winds above the United States. Made from a circuit of tubing filled with water and air, the sculpture contains a peristaltic pump that moves the fluid pattern along the 850mb streamlines from January 28th, 2013. Each loop is carefully placed and glued, totaling some 750 feet of 1/8" plastic tubing.

This project was the basis for a successful Kickstarter campaign in the fall of 2014, which won the award of Staff Pick. Proceeds from the sale of these Streamlines sculptures funded a 3-month trip around the United States, which you can read about on my blog page.

Road Trip: Inteviewing Engineers, Scientists and Artists

In 2014 I had just graduated from UNC at Asheville with a bachelors of science in Meteorology. My other classmates were headed off to federal and state agencies as scientists, or to TV channels to become broadcast meteorologists. But I had a strong hunch that my path was different. To help me discover that path, I designed a road trip across the country to interview scientists, engineers and artists about their professional and personal journeys. (This trip was funded from a successful Kickstarter campaign selling my weather sculptures, ‘Streamlines’. To learn more, see my portfolio). Over ten weeks and across 29 states I talked to people with diverse backgrounds and job titles like Traffic Engineer, Rocket Scientist, Emergency Manager, Community Organizer, Professor Emeritus, Social Worker, Interactive Artist, University Administrator and Aerospace Engineer. After this trip I knew that my path involved more education and I decided to return to school for a mechanical engineering degree. Today I am so thankful for the experience and perspective I gained on that road trip, and thankful for the connections which allowed me to grow as an engineer and a person.

As part of the road trip I interviewed Destin Sandlin about his professional and personal journey. See the videos on his YouTube channel SmarterEveryDay.

Mobile Taproom Trailer

While working for specialty drink company Rowdy Mermaid Kombucha in Boulder, CO in 2015, I proposed that they broaden their sales capabilities and increase brand awareness by building a mobile taproom trailer. It became my job to design, purchase, build and brand a successful replacement for their farmers market set-up. Pictured right is the taproom in operation, as well as the original design renderings.

Electronics Kit Instruction Manual and Activity

For an assignment for my technical writing class, we wrote an instruction manual for a technical activity. Since everyone in the class was an engineering student, my partner and I decided to go the extra mile and develop a fun activity kit to explore digital wave synthesis. We built a simple astable square wave oscillator and housed it in a modified pill bottle with neodymium magnet electrodes. For the manual we wrote a foreward, introduction for educators, list of parts, glossary and instructions for five activities that explore different ways of controlling the oscillator. To read a full copy of the instruction manual, click here.

Cup Holder for Crutches

While traveling the country with me in the fall of 2014, my friend Lizzie broke her ankle and was reduced to crutches for much of the trip. If you've ever been on crutches, you know the woes of losing self-sufficiency. For example, something as simple as holding coffee while walking becomes impossible. Mobility and dexterity should not be mutually exclusive. So I mocked up a quick-and-dirty cup holder for her that would not spill her drink while she crutches. Based on those gyroscopic sippy-cups for babies, two concentric rings allow a cup of coffee to pivot freely without spilling. Though rough, the design proved itself over a month of travel. I posted the design and instructions on Instructables.com, where it earned the award of Staff Pick.

Bus Stop Shelters

In the summer of 2016 I was commissioned to design several bus shelters that could be built cheaply and erected quickly. The project was part of a grassroots campaign to encourage Nashville City Council to allocate funds for better public transit infrastructure. The idea was largely inspired by Craig Wilkins' 2014 work in Detroit, MI.